Golden State Prioritizes Customers in Face of Parts Crunch

Just as there is no one reason why parts for fire apparatus have been difficult to come by in the past couple of years, there is no one simple solution to solve the problem. The COVID pandemic certainly had an impact on parts manufacturing – both in terms of access to raw materials as well […]

Susanville Fire Department wins 4th annual Fire Truck Face-Off

The small Susanville Fire Department – tucked in the remote northeastern corner of California – never had participated in the Fire Truck Face-Off before this year. But lack of experience was no hurdle for Fire Chief James Moore and his energetic crew, who emerged victorious in the 4th annual competition sponsored by Golden State Fire […]

To better serve customers, Golden State plans new Tracy service center

Customer convenience and customer service. Those two critical areas are the driving forces behind Golden State Fire Apparatus’ decision to pursue a second location in Tracy. The new facility will be similar to the company’s 35,000-square-foot location in Sacramento. By doubling capacity and building in Tracy, Golden State is confident it can provide faster turnaround […]

Susanville fire chief thrilled with new truck, unique service arrangement

Through three fire chiefs and nearly two decades, the city of Susanville has been writing grants to the federal government trying to find a way to buy a new fire truck. Finally last fall, good news arrived in the email inbox of Chief James Moore. The Federal Emergency Management Agency (FEMA) had approved a grant […]

Boulder Creek earns 2021 Fire Truck Face-Off championship

Like the firefighters who use it, Engine No. 2112 of the Boulder Creek Fire Protection District is a hard worker. It is a Pierce pumper that has rolled out to just about every call since its delivery last spring. It was especially busy in September during the horrific CZU Lightning Complex Fire, which burned 85,509 […]

GSFA founder remembers his good friend, Dave Boyd

Dave Boyd’s official title at Golden State Fire Apparatus was “new arrivals coordinator.” But his influence was felt in so many more ways. He was a role model for what a loyal employee should be. A great teammate. A barbecue chef extraordinaire. And, most of all, Boyd was a trusted confidante to the boss. “He […]

Two companies with big hearts

One from California, the other from Illinois – provide water to fire victims The CZU Lightning Complex Fire began late at night on Aug. 16 near Boulder Creek, a quiet little town deep in the redwood forest about 20 miles northeast of Santa Cruz, Calif. By the time it was contained Sept. 22, it had […]

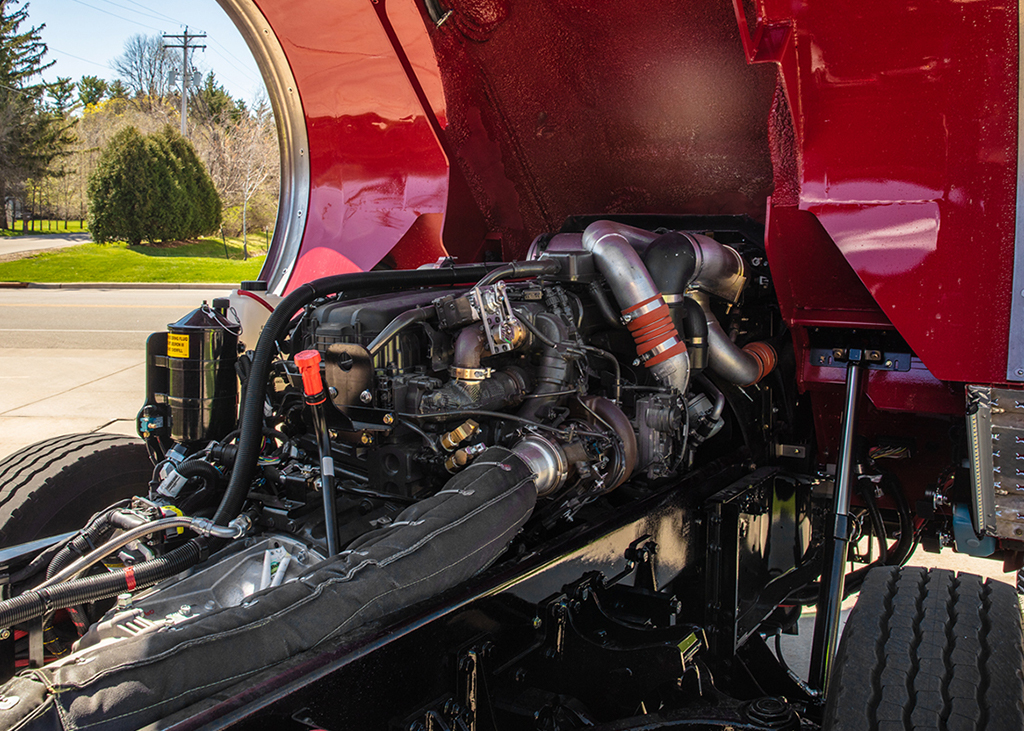

Pierce, PACCAR team up for first time on new MX-13 engine

Brad Hansen spent 20 years driving fire engines for the Sacramento City Fire Department. In his last six years, he was an Emergency Vehicle Operators Course (EVOC) instructor, teaching proper driving techniques to other firefighters, police officers and sheriff’s deputies. He knows his way around a piece of fire apparatus and appreciates the value of […]

Hanford earns title in 3rd annual Fire Truck Face-Off

College basketball fans across the country were disappointed this year when the NCAA cancelled the men’s tournament – commonly known as March Madness – because of health concerns related to COVID-19. That wasn’t the case, however, for the 3rd annual Fire Truck Face-Off sponsored by Golden State Fire Apparatus. Not even a pandemic could dim […]

Need parts? Golden State has just what you’re looking for

Each piece of equipment sold by Golden State Fire Apparatus is expected to perform under the most rugged and demanding conditions. When lives are on the line and property is at risk, nothing else is acceptable. Given the circumstances in which vehicles routinely operate, the need for quality maintenance and timely repairs is crucial. Expensive […]